Context

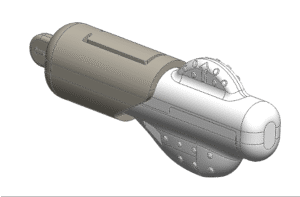

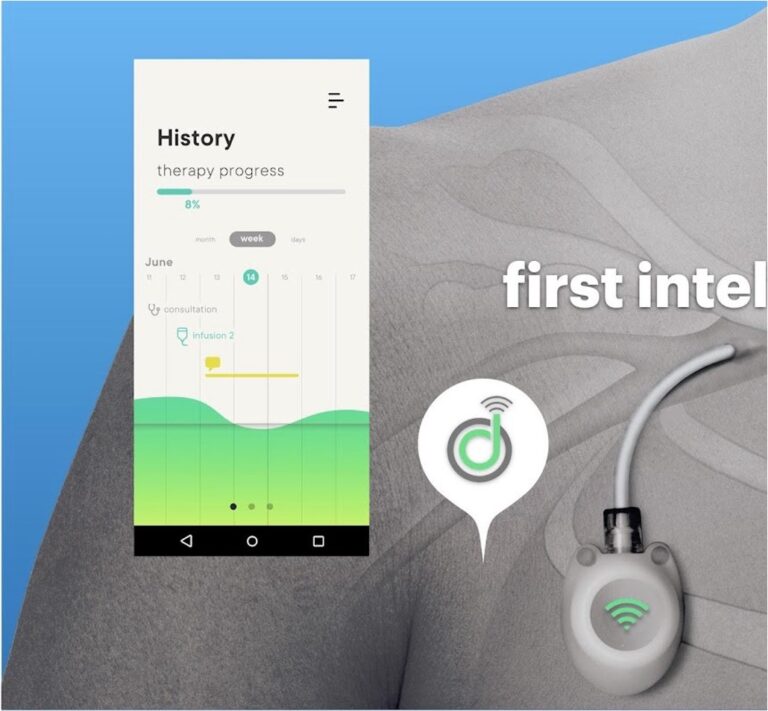

A pre-seed oncology device startup partnered with iO Lifescience to develop the first functional prototype of a 3D-printed delivery system for prostate brachytherapy. The goal was to create a clinician and patient-friendly solution that integrates seamlessly with TRUS/CT workflows and standard stepper/needle systems, supporting pre-clinical evaluation and early clinical readiness to attract investors.

Challenges

The project demanded precision, speed, and compliance from day one:

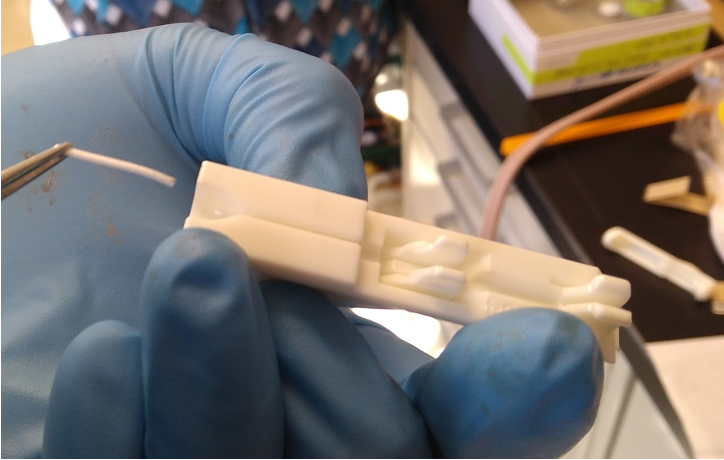

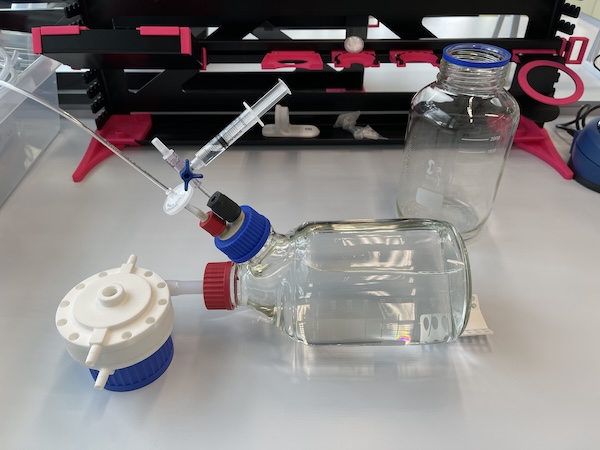

- Rapid prototyping: Translate clinical sketches into CAD under ISO 13485 design controls, using medical-grade SLA/SLS 3D printing.

- Accuracy & imaging: Deliver ≤3 mm needle-guidance precision with radiopaque and sonoreflective features visible under TRUS/CT.

- Sterilization & biocompatibility: Select materials compatible with EtO, gamma, and steam sterilization; plan ISO 10993 testing.

- Workflow & usability: Ensure compatibility with standard templates and 17–18 G needles, validated through formative human-factors testing.

- Manufacturing & verification: Qualify a QMS-capable 3D-printing partner, define DFM rules, and document a verification strategy aligned with clinical protocols.

Outcomes

- Concept-to-alpha in 6 weeks, beta/clinical units in 10 weeks.

- Performance verified: ≤3 mm mean targeting error; consistent TRUS/CT visibility.

- Clinical readiness: Delivered sterilizable kits, usability labeling, and a complete V&V matrix.

- Manufacturing maturity: DFM guardrails, consolidated BOM, and COGS model established.

- Investment traction: Prototype data and documentation supported follow-on funding and clinical engagement.