Traditional medical device development often follows a rigid, linear “waterfall” model. While seemingly robust for highly regulated fields, this approach can be slow and expensive, especially when design flaws are discovered late in the process, triggering costly rework. This is where rapid prototyping in medtech and lean medical device development emerge as powerful strategic advantages, allowing startups to innovate faster, de-risk their ventures, and accelerate their journey to commercialization.

The Pressure Cooker of Medtech Development

Medtech startups face immense pressure:

- Intense Competition: The market is crowded with both established players and agile new entrants.

- High Development Costs: R&D, clinical trials, and regulatory submissions demand significant capital.

- Long Regulatory Pathways: Ensuring safety and efficacy requires meticulous documentation and testing.

In this environment, optimizing every stage of development becomes crucial.

Rapid Prototyping: Building, Testing, Learning – Fast

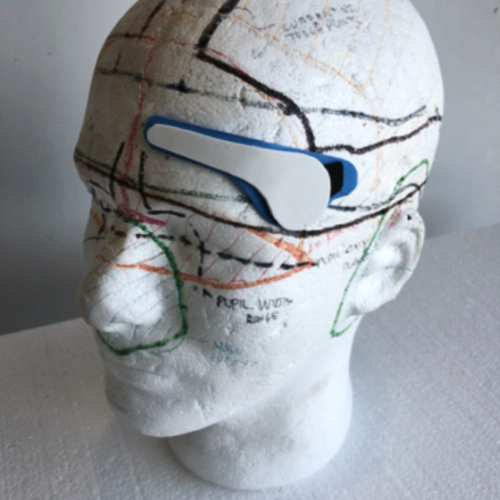

Rapid prototyping is the ability to quickly create functional or visual models of a product, allowing for early testing and iteration. In medtech, this moves beyond mere concept visualization to validating form, fit, and even basic function in a simulated or real-world use environment.

Technologies Fueling Rapid Prototyping in Medtech:

- 3D Printing (Additive Manufacturing): Revolutionized rapid prototyping. Technologies like Stereolithography (SLA) for high-resolution models, Fused Deposition Modeling (FDM) for functional parts, and Selective Laser Sintering (SLS) for strong, complex geometries allow for quick creation of custom components, surgical guides, anatomical models, and even functional device enclosures.

- CNC Machining: For higher precision or specific material requirements, CNC (Computer Numerical Control) can quickly produce prototypes from various plastics and metals.

- Rapid Tooling & Molding: Techniques like soft tooling or silicone molding enable the production of small batches of prototypes with production-like materials and processes.

Benefits of Rapid Prototyping in Medtech:

- Early Validation of Design: Test ergonomics, user interaction, and physical fit much earlier than traditional methods.

- Faster User Feedback: Get prototypes into the hands of clinicians and patients for crucial feedback, identifying usability issues and desired features before significant investment.

- Reduced Design Flaws: Catching errors in the prototyping phase is vastly cheaper than discovering them during clinical trials or manufacturing.

- Cost Efficiency: Avoid expensive re-tooling and large-scale manufacturing changes by refining designs incrementally.

Lean and Agile Principles for Medical Device Development

Beyond rapid prototyping, adopting lean medical device development and agile methodologies further transforms the development paradigm. These principles, originating from manufacturing and software development, emphasize minimizing waste, maximizing value, and responding to change.

- Lean Startup: This methodology centers on the “Build-Measure-Learn” feedback loop. Instead of building a perfect product upfront, you create a Minimum Viable Product (MVP) – the simplest version of your device that delivers core value and allows you to gather validated learning from users. This iterative approach ensures you’re building what users actually need, quickly.

- Agile Development: Focuses on iterative cycles (“sprints”), continuous improvement, and cross-functional teams working collaboratively. While software-centric, its principles can be adapted for hardware development.

Adapting to Regulations: Applying lean and agile in medtech requires a careful balance. Regulations like ISO 13485 (Quality Management Systems) and IEC 62304 (Medical Device Software Lifecycle Processes) demand rigorous documentation and design control. However, agile documentation methods and integrating regulatory milestones into sprints can allow for flexibility within a compliant framework. The key is to manage risk proactively and document decisions clearly, rather than relying on a rigid, waterfall-style paper trail.

How Rapid Prototyping & Lean Accelerate Time to Market

By embracing these methodologies, medtech startups can significantly shorten their development cycles:

- Early Problem Identification: Flaws are uncovered and fixed when they are cheapest to address, preventing costly delays down the line.

- Faster User Feedback & Iteration: Designs are constantly refined based on real-world input, leading to a more optimized product that truly meets user needs.

- Optimized Resource Allocation: Focus on developing only the features that users value most, avoiding wasted effort on unneeded complexities.

- De-risking the Process: Incremental development and continuous testing reduce technical, market, and regulatory risks.

- Enhanced Investor Confidence: Demonstrating quick progress, user validation, and efficient resource use can attract and retain funding.

Practical Strategies for Implementation

- Invest in Design Sprints: Short, focused periods dedicated to rapid ideation, prototyping, and testing of a specific feature or concept.

- Integrate Simulation: Use virtual reality or advanced simulation tools to test device performance and user interaction without physical prototypes.

- Embrace Digital Tools: Leverage collaborative design platforms, cloud-based project management, and digital lab notebooks to streamline workflows and data sharing.

- Foster Cross-Functional Teams: Encourage engineers, designers, clinicians, and regulatory experts to work closely from the outset.

- Build a “Prototyping Mindset”: Encourage a culture of continuous experimentation and learning from failures.

The Incubator’s Role in Fostering Speed

A virtual medtech incubator like iolifescience.com is uniquely positioned to help startups adopt these accelerating methodologies:

- Access to Resources: Connecting startups with rapid prototyping facilities, 3D printing services, or even providing guidance on setting up in-house capabilities.

- Expert Mentorship: Offering guidance from seasoned professionals on implementing lean principles, agile project management, and integrating design control with iterative development.

- Strategic Networks: Linking startups with potential users for early feedback, or with regulatory consultants who understand agile approaches.

- Best Practice Sharing: Facilitating knowledge exchange on effective tools and processes for iterative design in medical technology.

Conclusion

In the competitive landscape of medical technology, speed is a strategic imperative. By consciously integrating rapid prototyping and lean development methodologies, medtech startups can dramatically reduce time to market. This isn’t about cutting corners; it’s about building smarter, learning faster, and consistently de-risking the development process. The result is not just a more efficient pathway to market, but ultimately, the ability to bring life-changing innovations to patients with greater agility and impact.