Context

A seed-stage oncology startup partnered with iO Lifescience to turn a concept for an implantable biosensor with mobile and cloud connectivity into a clinical-grade, investor-ready product. Acting as fractional COO, iO led the program from feasibility to exit, covering pre-clinical studies, full product development, QMS implementation, supplier qualification, and DHF completion.

Challenges

The program demanded tight integration of engineering, compliance, and execution at startup speed:

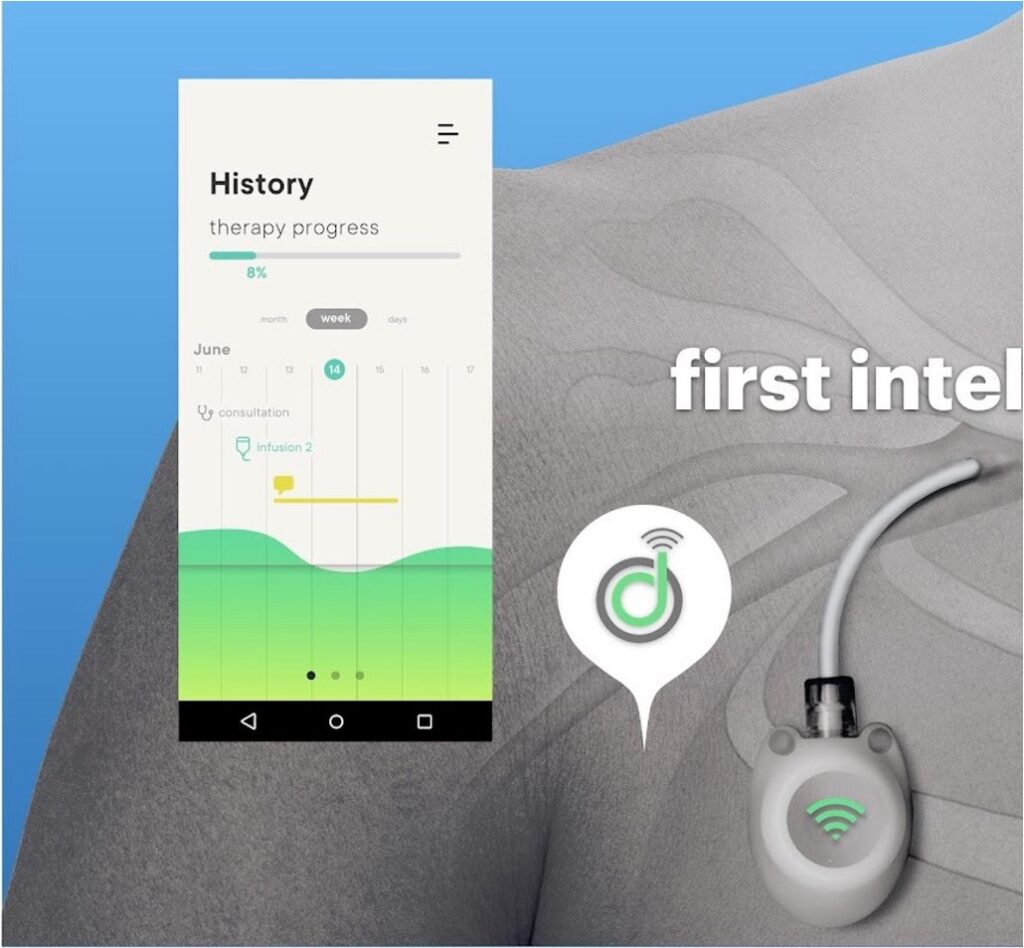

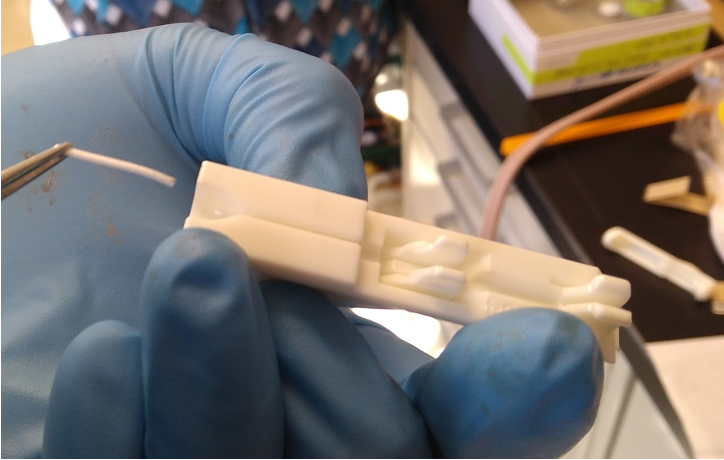

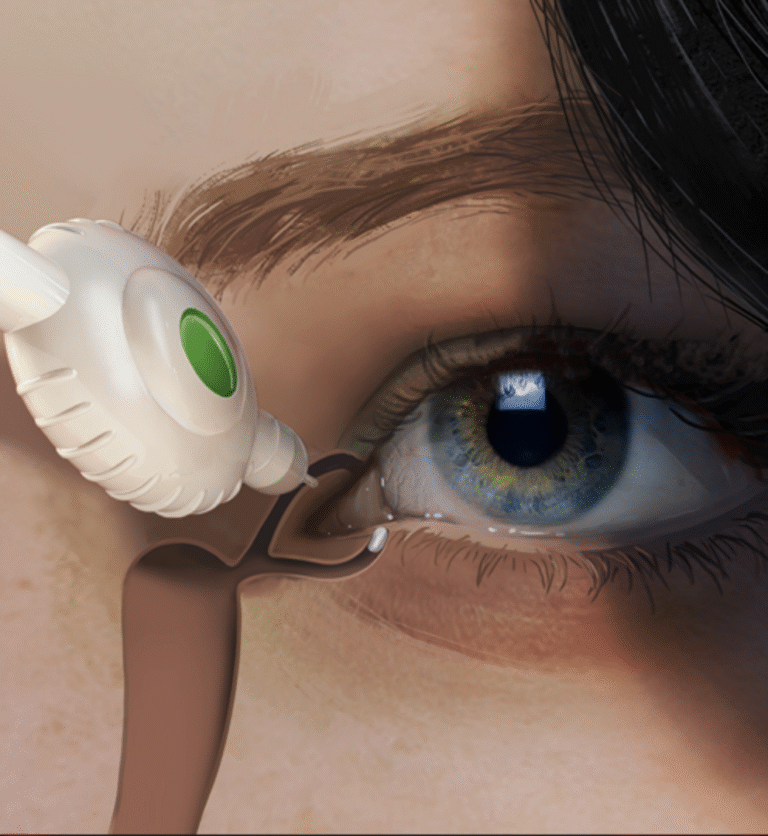

- System complexity: Miniaturized implantable sensor, inductive power, secure telemetry, and connected mobile app.

- Human factors: Safe, repeatable implant/explant workflow with clear OR and at-home guidance.

- Biocompatibility & reliability: Material selection, encapsulation, sterilization, and long-term stability.

- Regulatory & evidence: GLP-aligned pre-clinical studies, risk management, usability validation, and ISO-standard documentation.

- Manufacturing scale: DFM/DFA, supplier audits, and process validation (DQ/IQ/OQ/PQ) for volume production.

iO Lifescience provided program leadership, system engineering, rapid prototyping, human-factors testing, regulatory strategy, supplier scaling, and quality system implementation under ISO 13485.

Outcomes

- Alpha prototypes in 4 weeks; beta units for clinical evaluation shortly after.

- Pre-clinical studies met go/no-go criteria for safety, signal integrity, and workflow reliability.

- Human factors: ≥90% success across implant tasks; optimized OR guides reduced setup time.

- Regulatory & quality: Complete DHF with traceability and validated RMF/URRA; pre-sub feedback integrated.

- Scale & cost: Qualified suppliers, validated processes, and COGS model reduced projected costs.

- Investor & exit readiness: Robust data package, supplier commitments, and regulatory maturity enabled follow-on funding and successful acquisition.