Context

A pre-seed renal-care startup partnered with iO Lifescience to transform a clinical concept into pre-clinical-ready prototypes aimed at improving the reliability and safety of renal access during dialysis and related interventions. The objective: reduce complications and establish a scalable path toward manufacturing and early clinical studies.

Challenges

The development required balancing physiological performance, biocompatibility, and manufacturability:

- Rapid concept realization: Translate clinical sketches into CAD and EVT prototypes under ISO 13485 controls.

- Physiology-aligned design: Deliver target flow and stability while minimizing trauma and thrombosis.

- Materials & sterilization: Identify suitable polymers/metals, coatings, and sterilization paths (EtO/steam).

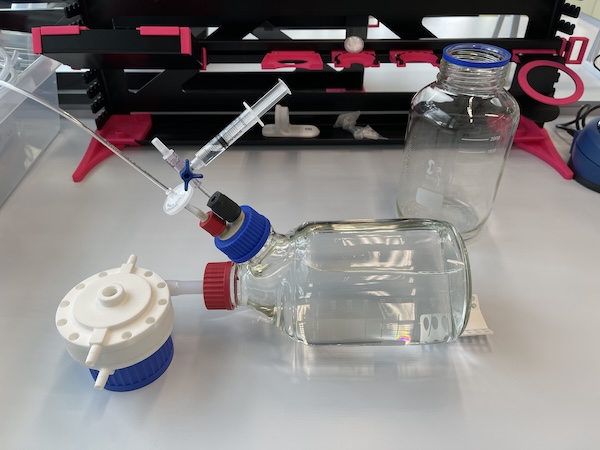

- Pre-clinical readiness: Design GLP-aligned large-animal protocols with custom fixtures and bench models.

- Human factors: Develop intuitive delivery tools with clear feedback for interventionalists.

- Scalable manufacture: Establish DFM/DFA rules, pilot tooling, and supplier qualification for future builds.

iO Lifescience led mechanical engineering, prototype fabrication, pre-clinical study support, usability testing, verification planning, and supplier sourcing.

Outcomes

- Concept-to-alpha in 8 weeks, beta and delivery tools in 14 weeks for animal testing.

- Bench-to-in-vivo correlation: Validated flow, sealing, and placement metrics predicting in-animal outcomes.

- Animal studies: Met all predefined success criteria, enabling transition to clinical planning.

- Manufacturing readiness: Scalable architecture and COGS model defined with qualified suppliers.

- Regulatory foundation: Initial risk file, usability analysis, and verification matrix completed.

- Investor traction: Pre-clinical data and manufacturing strategy supported follow-on financing.